PROCESS

Attention to Detail in the Manufacturing Process

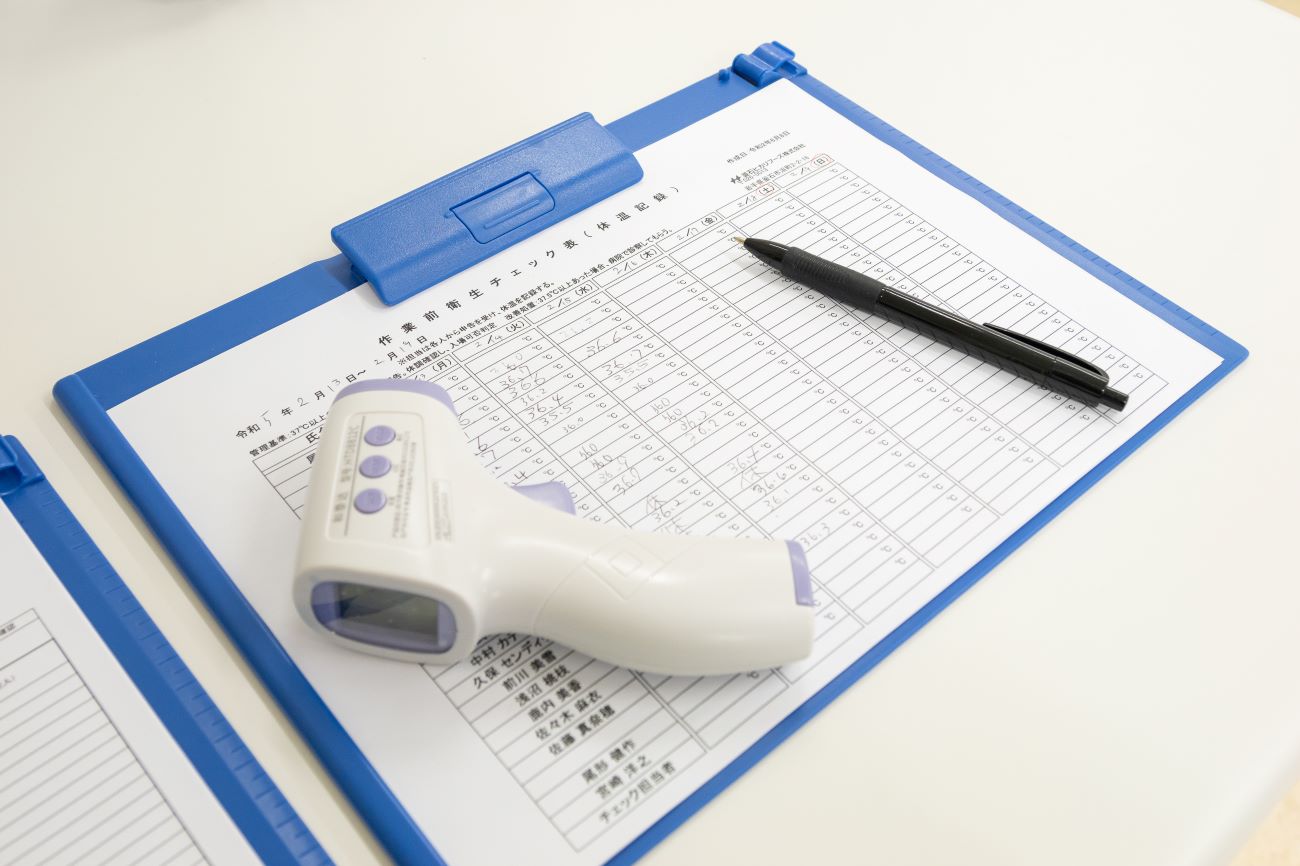

Commitment to Product Safety and Quality

In order to deliver fresh and delicious seafood from Sanriku Kamaishi to all parts of Japan in a safe and secure manner, we collaborate with universities, national and local governments, and businesses to develop and implement advanced technologies. Food safety is our top priority, and we continuously strive for improvement, enhancing work efficiency and ensuring safety throughout our operations.

日本語

日本語